WFS

WFS

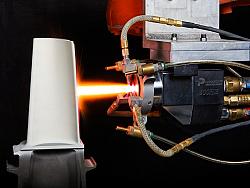

Flame spraying includes low-velocity powder flame, rod flame, and wire flame processes and high-velocity processes such as HVOF and the detonation gun (D-Gun) process.

In wire flame spraying, the primary function of the flame is to melt the feedstock material. A stream of air then atomizes the molten material and propels it toward the work piece. Spray rates for materials such as stainless steel are in the range of 0.5 to 9 kg/h. Again, lower melting point materials such as zinc and tin alloys spray at much higher rates. Substrate temperatures often range from 95 to 205 °C because of the excess energy input required for flame melting. In most thermal spray processes, less than 10% of the input energy is actually used to melt the feedstock material.