Cement

Cement

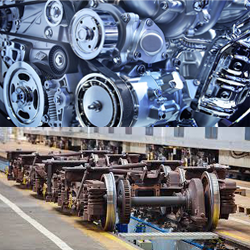

The manufacture of cement creates a demanding environment for almost all equipment to be coated and hard faced. In the cement industry, parts are under conditions of high temperature and subject to severe wear. The wear rate depends on the materials used, the type and design of the mill, and working temperatures. Failure to control the mechanisms of surface degradation will result in reduced efficiency, damage to the quality of materials, increased energy consumption, high vibrations, and ultimately the risk of damage to the entire system.

Some examples of parts on which thermally sprayed coatings are applied in cement industry include:

- Kiln Support Roll

- Calendar Roll

- Furnace Roll

- Pinion Shaft

- Compressor Shaft

- Fan Shaft

- Cone Crusher and Mechanical Seal

- Burner Tips and Sleeves

- Thermo Wall