APS

ASP

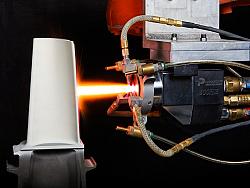

The conventional plasma spray process is commonly referred to as air or atmospheric plasma spray (APS). Plasma temperatures in the powder heating region range from about 6000 to 15,000 °C, significantly above the melting point of any known material. To generate the plasma, an inert gas (typically argon or an argon-hydrogen mixture) is superheated by a dc arc. Powder feedstock is introduced via an inert carrier gas and is accelerated toward the work piece by the plasma jet. Provisions for cooling or regulating the spray rate may be required to maintain substrate temperatures in the 95 to 205 °C range. Commercial plasma spray guns operate in the range of 20 to 200 kW. Accordingly, spray rates greatly depend on gun design, plasma gases, powder injection schemes, and materials properties, particularly particle characteristics such as size, distribution, melting point, morphology, and apparent density.