ARC

arc

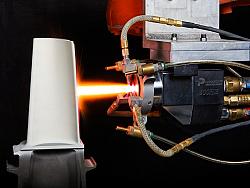

In the electric arc spray process (also known as the wire arc process), two consumable wire electrodes connected to a high-current direct-current (dc) power source are fed into the gun and meet, establishing an arc between them that melts the tips of the wires. The molten metal is then atomized and propelled toward the substrate by a stream of air. The process is energy efficient because all of the input energy is used to melt the metal.

Spray rates are driven primarily by operating current and vary as a function of both melting point and conductivity. Generally materials such as copper-base and iron-base alloys spray at 4.5 kg /100 A/h. Zinc sprays at 11 kg /100 A/h. Substrate temperatures can be very low, because no hot jet of gas is directed toward the substrate. Electric arc spraying also can be carried out using inert gases or in a controlled-atmosphere chamber.